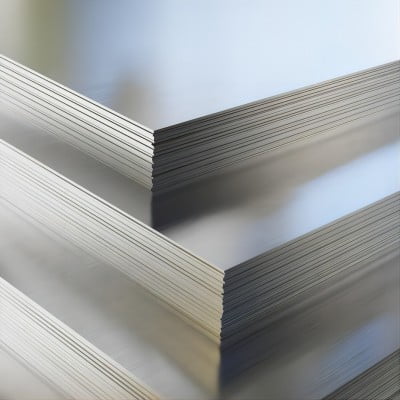

| Stainless Steel Sheet, Coil And Strip | |

| Grade | 304, 304/304L, 316 & 316/316L. |

| Thickness (mm) | 0.45 to <5.0. |

| Width (mm) | 914, 1219, 1500, 2000 & customer specific strip. |

| Length (mm) | 1829, 2438 & customer specific cut-to-length. |

| Finish | 2B, No.4, BA, No.1 (HRAP) & customer specific polish. |

| Standard coating | Paper interleaf & PE. |

| Optional coating | Laser & Deep drawing PVC. |

| Plasma profiles | To customer drawings. |

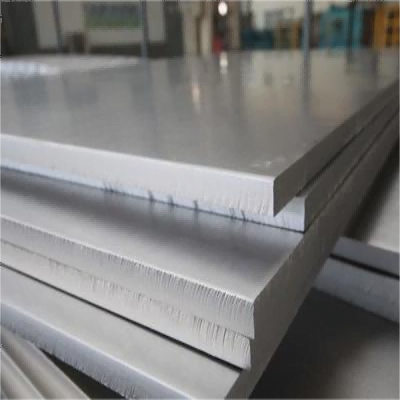

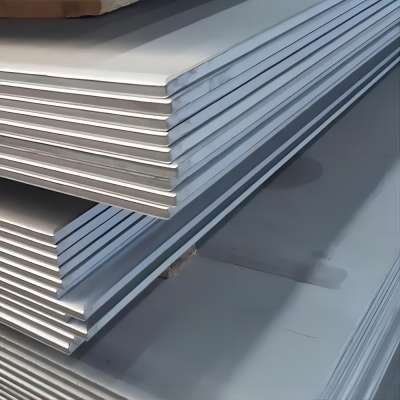

| Stainless Steel Plate | |

| Grade | 304/304L, 316/316L, 4003/CR12, 2205 & 253MA. |

| Thickness (mm) | 5.0 to 50.0. |

| Width (mm) | 1250 (grade 4003), 1500, 2000 & 2500. |

| Length (mm) | 3000, 6000 & customer specific cut-to-length. |

| Finish | 2B (to 8mm) & No.1 (HRAP). |

| Plasma profiles | To customer drawings. |

Specification

ASTM A240M. Chromium and chromium-nickel stainless steel plate, sheet and strip for pressure vessels and for general applications.

ASTM 480M. General requirements for flat rolled stainless and heat-resisting steel plate sheet and strip.

Product Finish

Stainless steel coil and plate is supplied from mills throughout the world in hot rolled and cold rolled conditions.

| Product | Product Process | Description | Abbreviation |

| Hot rolled | Hot rolled, annealed and pickled. | Condition and finish preferred for corrosion-resisting and heat-resisting applications. Typically available in thickness 5mm and above. | No. 1 or HRAP |

| Cold rolled | Hot rolled, annealed, descaled, cold rolled, annealed, pickled, final skin pass rolled. | Smooth finish achieved by cold rolling, then annealing and pickling, followed by skin pass rolling. Typically available in thickness up to 8mm. | 2B |

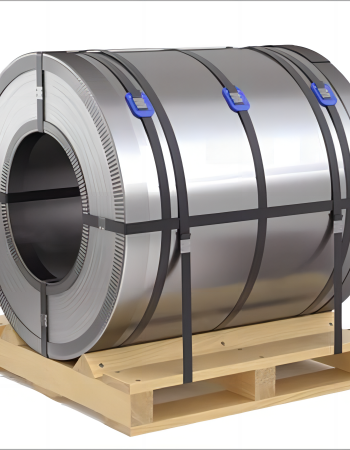

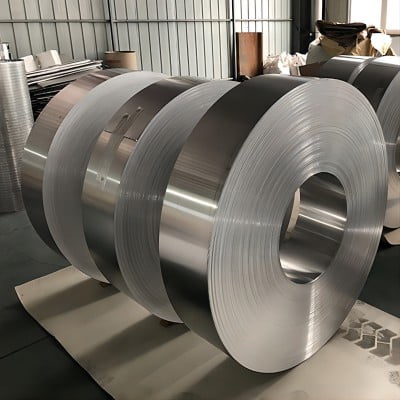

Stainless Steel Flat Product Produced From Coil

The internationally recognised crossover thickness between what is referred to as sheet and plate is 5.0mm. This is specified in ASTM A480M. Therefore, sheet thickness is less than 5.0mm and plate is 5.0mm and over.

It is common practice for large stainless steel coils to be imported into Australia and processed by a specialty metals service centre into smaller coils, sheet, strip and plate. Product over 12mm is imported into Australia as plate only.

Surface Finishes

The following stainless steel finishes are commonly used for the Australian market.

| Finish | Description |

| 2B | The general-purpose, cold rolled, smooth finish obtained as a result of a final light pass through polished rolls at the mill. |

| BA | Bright annealed finish is a bright, cold rolled, highly reflective finish retained by final annealing in a controlled atmosphere furnace. The finish has large application in the appliance and automotive industry and as a decorative finish in architecture. The brightness and reflectivity is a function of thickness and grade. Consultation is recommended prior to specification in architectural applications. BA finish is usually supplied with a PE or PVC coating as a surface protection. |

| No. 4 | Produced from 2B finish often by a service centre rather than the production mill. It is a general-purpose ground polished finish used widely for kitchen equipment and applications requiring a decorative linished finish. No.4 finish is usually supplied with a PE coating as a surface protection. |

| No.8 | Highly reflective ‘mirror’ finish. Produced from 2B finish by polishing with successive finer abrasives following by extensive buffing. Mainly used in architectural applications. |

| Customer-specific | A service centre with polishing equipment can produce special finished for specific applications. |